Design, Engineering, and Fabrication

APL innovations enabled humankind’s closest approach to the Sun and the world’s first-ever planetary defense mission; created a standard for cybersecurity for industrial control systems; led to the development of the world’s first neurally integrated prosthetic limb; and are paving the way to breakthrough technology in operational quantum sensors.

At APL, our culture of taking bold risks, brought to life through inventive prototyping and informed by deep technical expertise, is the basis for our efforts to not merely anticipate the future, but create it.

Capabilities

Electronics Design and Fabrication

We provide an integrated capability to build hardware ranging from quick-turn prototypes to fully qualified spaceflight assemblies and from nanoscales up to fully integrated electronic packages for deployment on land, undersea, and on space systems.

Mechanical Fabrication

Our science-based manufacturing and prototyping facility provides full-spectrum support, from conceptual R&D through configured hardware production.

Electrical and Mechanical Engineering

We excel in electrical and mechanical engineering, mechatronics, electronics packaging, systems integration, and multiscale modeling.

Pushing the Boundaries of Bold Innovation

Concept Design and Realization

The Concept Design and Realization Branch within APL’s Research and Exploratory Development Department provides an array of engineering, design, and fabrication capabilities that broadly support the Laboratory’s mission and sponsored work. Learn more about the wide-ranging work of the branch and how it directly contributes to APL’s position as a unique resource to the nation.

Featured Labs and Facilities

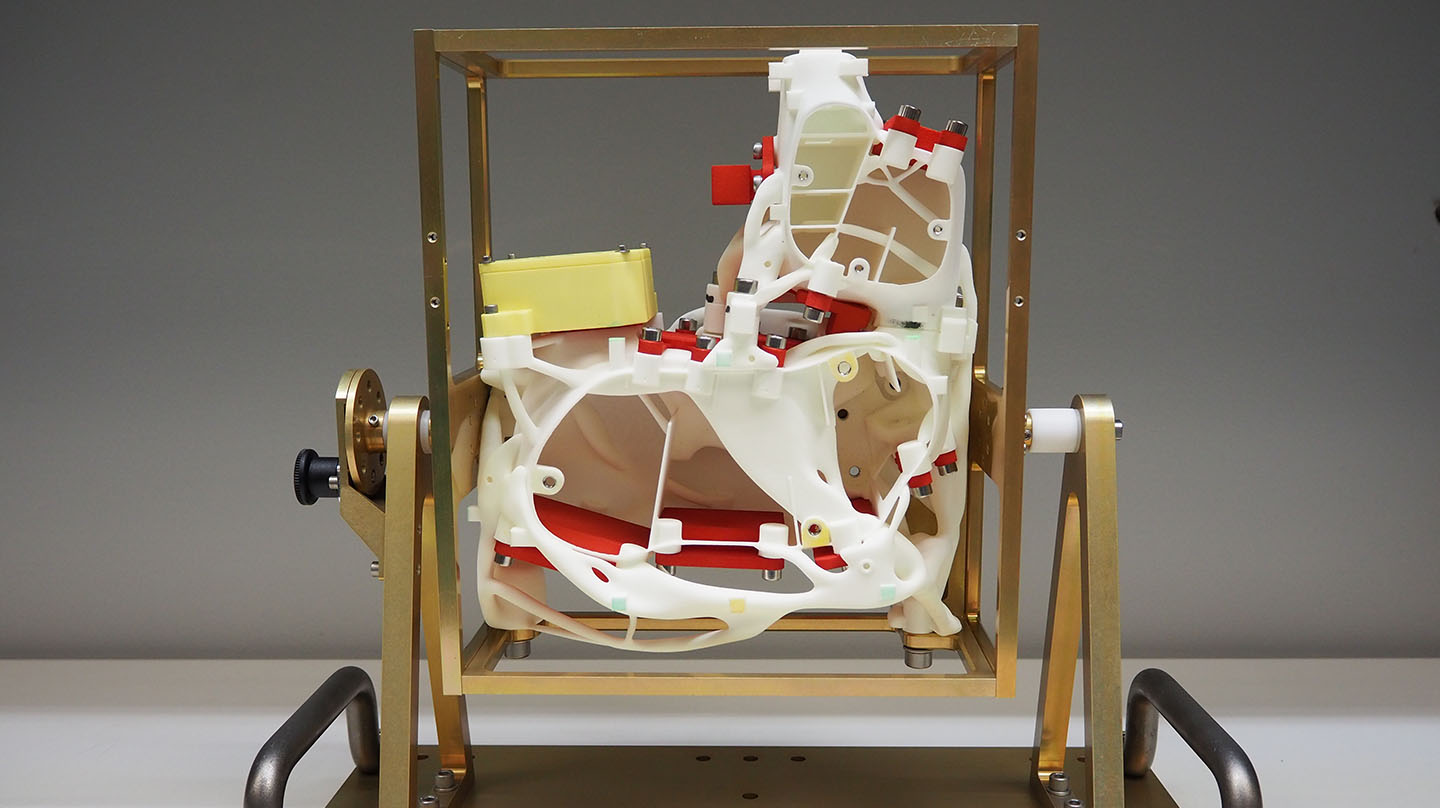

Additive Manufacturing Center

The Additive Manufacturing Center (AMC) adds value to sponsored programs in ways that cannot be achieved by traditional manufacturing. The AMC has a growing suite of industrial additive manufacturing machines (currently six polymer and six metal additive manufacturing systems) and multiple experimental test-bed printers. The center is advancing the state-of-the-art capabilities in additive manufacturing through applied materials research and development and integration of innovative process control methods to maximize the potential of enabling novel hardware solutions for critical challenges.

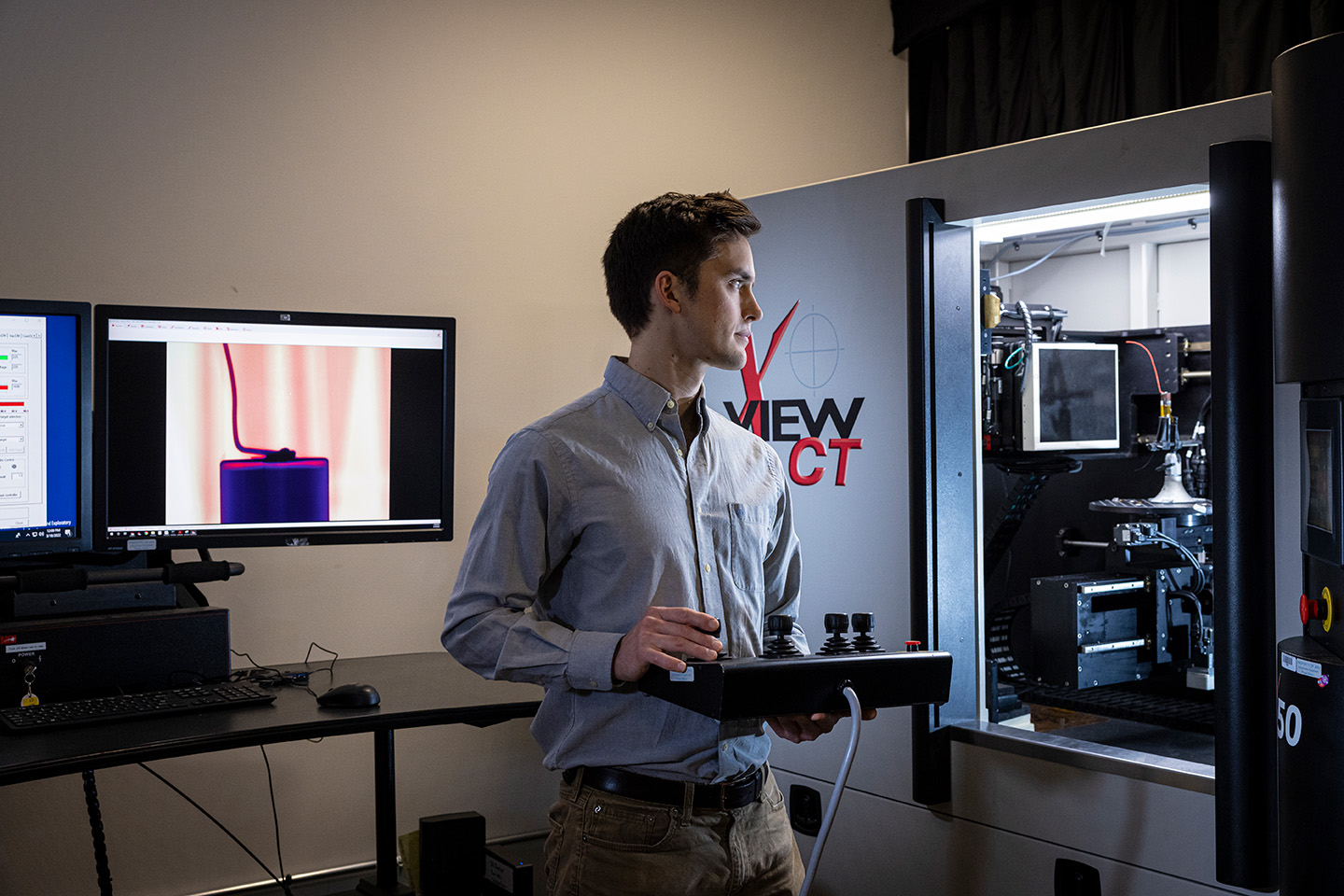

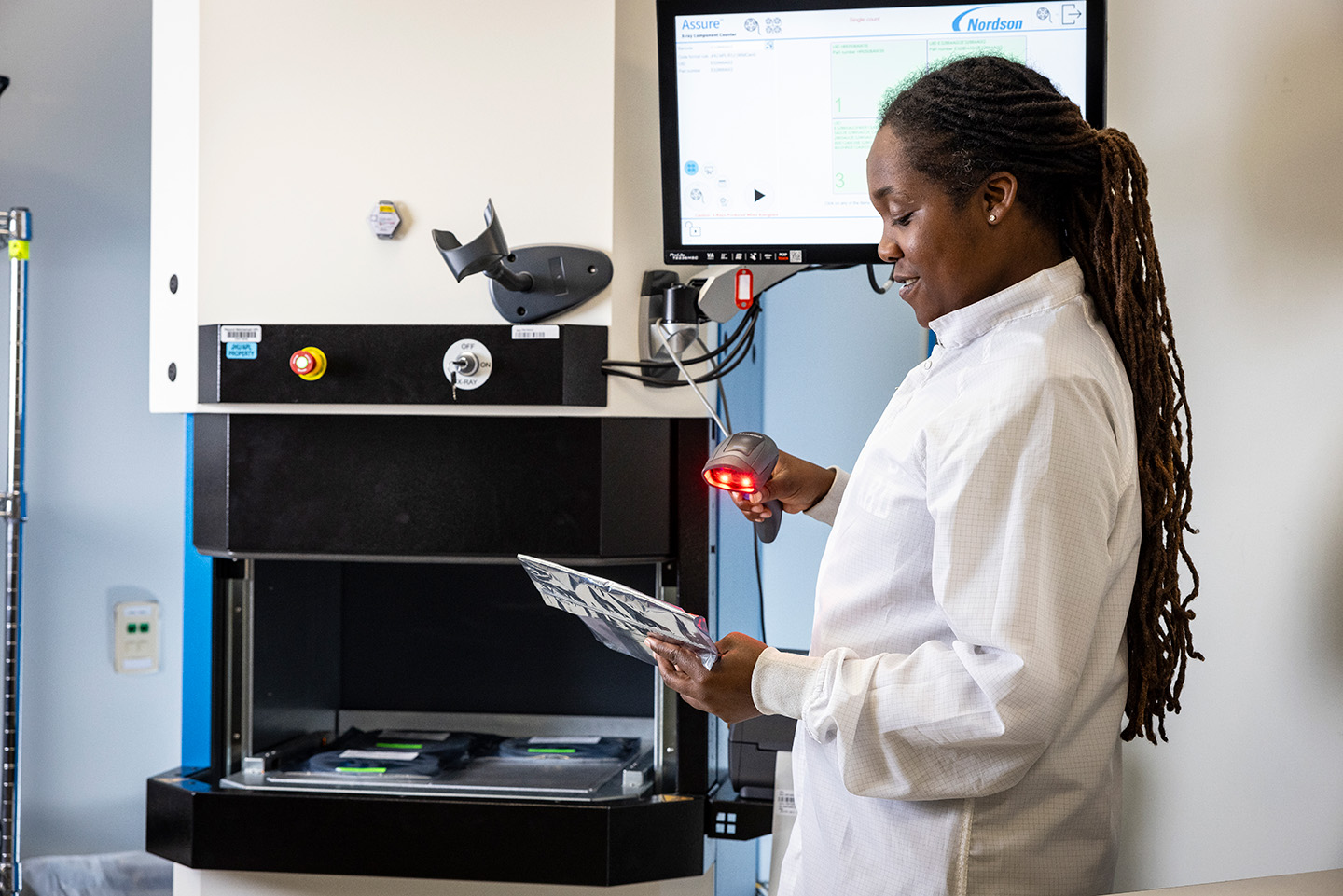

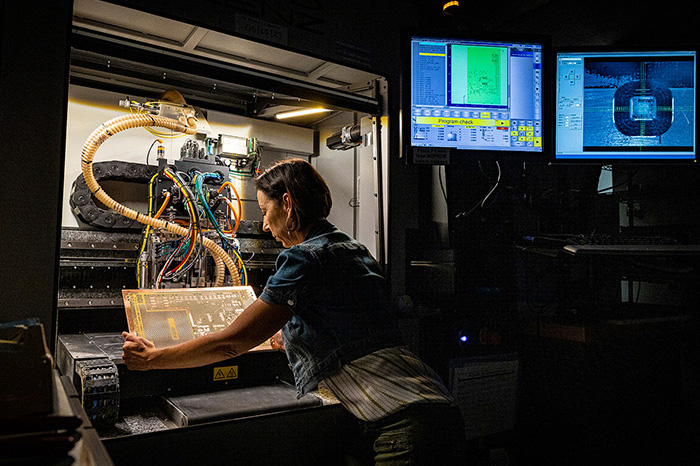

Advanced Electrical Fabrication Laboratory

The Advanced Electrical Fabrication (AEF) Laboratory provides a variety of capabilities. Our subject-matter experts can advise on novel manufacturing techniques, provide design for manufacturing guidance, and facilitate fabrication needs. From forward-leaning nanoscale research to high-reliability spacecraft assembly to quick-turn deployable prototypes, the AEF Lab is ready to physically realize products in a number of domains, such as printed circuit boards, electrical assembly, advanced plating, and micro/nanofabrication.

Mechanical Fabrication Laboratory

The Mechanical Fabrication facility delivers prototypes and fully qualified hardware for complex systems (such as space and undersea) and research programs. Our exceptionally talented staff utilizes the unique manufacturing capabilities in a 24,000-square-foot state-of-the-art manufacturing facility, which includes CNC multi-axis milling and turning, welding, precision sheet metal fabrication, laser engraving, and waterjet and laser cutting. Our experts engage with engineers, designers, and sponsors throughout the Laboratory, providing recommendations on manufacturing feasibility and ensuring their hardware goals are achieved.

Related News

Learn more about recent work that relied on APL’s design and fabrication expertise.

An Accelerated Paradigm for Developing Mission-Critical Materials Sep 17, 2025

Johns Hopkins APL, Navy Team up to Advance Additive Manufacturing for Critical Missions Jun 17, 2025

Catching Additive Manufacturing Flaws with Nanoseconds to Spare May 9, 2024

Johns Hopkins APL Researchers Take Additive Manufacturing to New Heights Mar 21, 2024

GUSTO Mission Breaks NASA Record for Longest Flight by Heavy Lift Balloon Feb 24, 2024

NASA’s Balloon Mission GUSTO Mapping the Space Between the Stars Dec 20, 2023

Sailors 3D-Print Critical Component at Sea Using Johns Hopkins APL-Installed Hybrid Manufacturing System Nov 13, 2023

GUSTO Balloon Observatory Mission Ships Out in Preparation for Antarctic Launch Jul 17, 2023