News

Johns Hopkins APL Researchers Take Additive Manufacturing to New Heights

When Zach Post was approached about leading a study to develop a framework for additively manufacturing (colloquially called 3D printing) a new space instrument for detecting air pollution, it was an opportunity he couldn’t pass up. A materials engineer at the Johns Hopkins Applied Physics Laboratory (APL) in Laurel, Maryland, Post had been interested in expanding his career in fabricating additively manufactured samples and parts to include performing the data analysis that happens before and after. And here, a project doing just that fell right into his lap.

“It was an exciting opportunity, one that perfectly fit my goals and interests to really see how processing can alter a material’s performance,” Post said.

What nobody anticipated, however, was that the project would also make a big splash in the additive manufacturing community. The paper describing the team’s framework for selecting the instrument’s material and printing process, which Post authored with team members from APL and the Netherlands Organisation for Applied Scientific Research (TNO), has now won two awards: the Light Metal Subject Award for aluminum alloys and the overall Light Metals Award, both from The Minerals, Metals & Materials Society (TMS) — one of the largest materials societies in the United States.

The team received the awards on March 6 at the TMS 2024 annual meeting in Orlando, Florida.

“It wasn’t even on our radar that the paper would be considered for one award, let alone two,” said Walter Zimbeck, an APL electrical and computer engineer, adviser to Post and study co-author who oversaw the print process.

But as an emerging field, additive manufacturing still rarely has such a clear, direct application to a final product. That fact is what many on the team believe made the paper stand out: having the application in mind from the beginning and allowing that vision to hone the process of material characterization, development and selection.

New Methods

The space instrument that motivated the project is the Compact Hyperspectral Air Pollution Sensor Demonstrator (CHAPS-D). Small enough to fit onto a shoebox-sized satellite, the instrument will carry sensors and specially designed mirrors powerful enough to isolate sources of air pollution at roughly half a square mile (1 square kilometer) from low Earth orbit, an unparalleled capability.

NASA’s Earth Science Division funded the project in 2019, with the request that it somehow include additive manufacturing. The method’s ability to more quickly and less expensively create parts that weigh a fraction of those created using typical machining procedures has made it appealing to the space industry, where time, cost and weight constraints are the norm.

“You wouldn’t have to machine something difficult or impossible or spend time assembling it,” said APL’s Bill Swartz, the principal investigator of CHAPS-D. “You could, in theory, just print it out.”

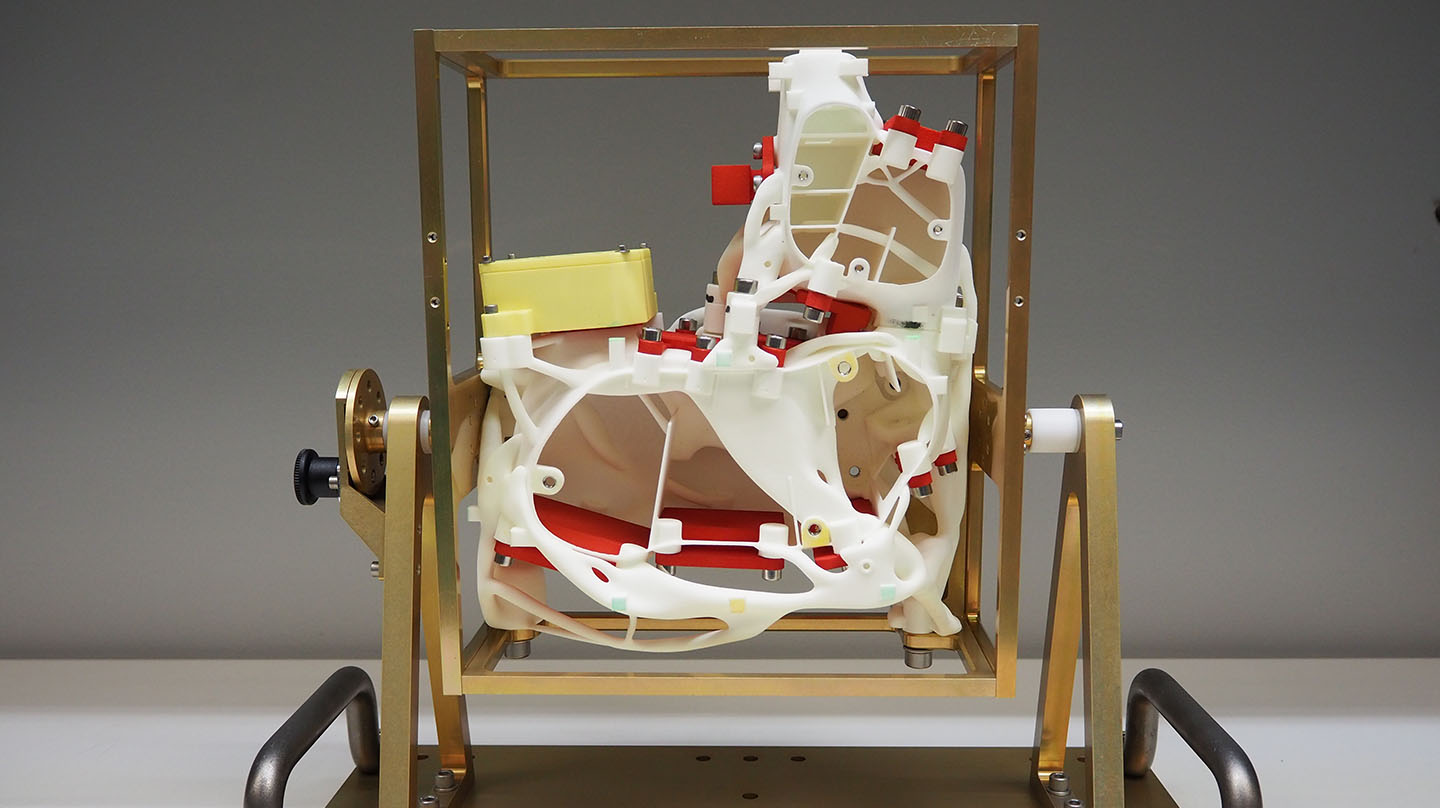

Given CHAPS-D’s miniaturization, additive manufacturing engineers from APL’s Research and Exploratory Development Department and their collaborators from TNO decided to design the instrument using topology optimization — a computational method that adjusts the distribution of material in a structure so it’s only used where it is absolutely necessary — and print out the instrument’s body.

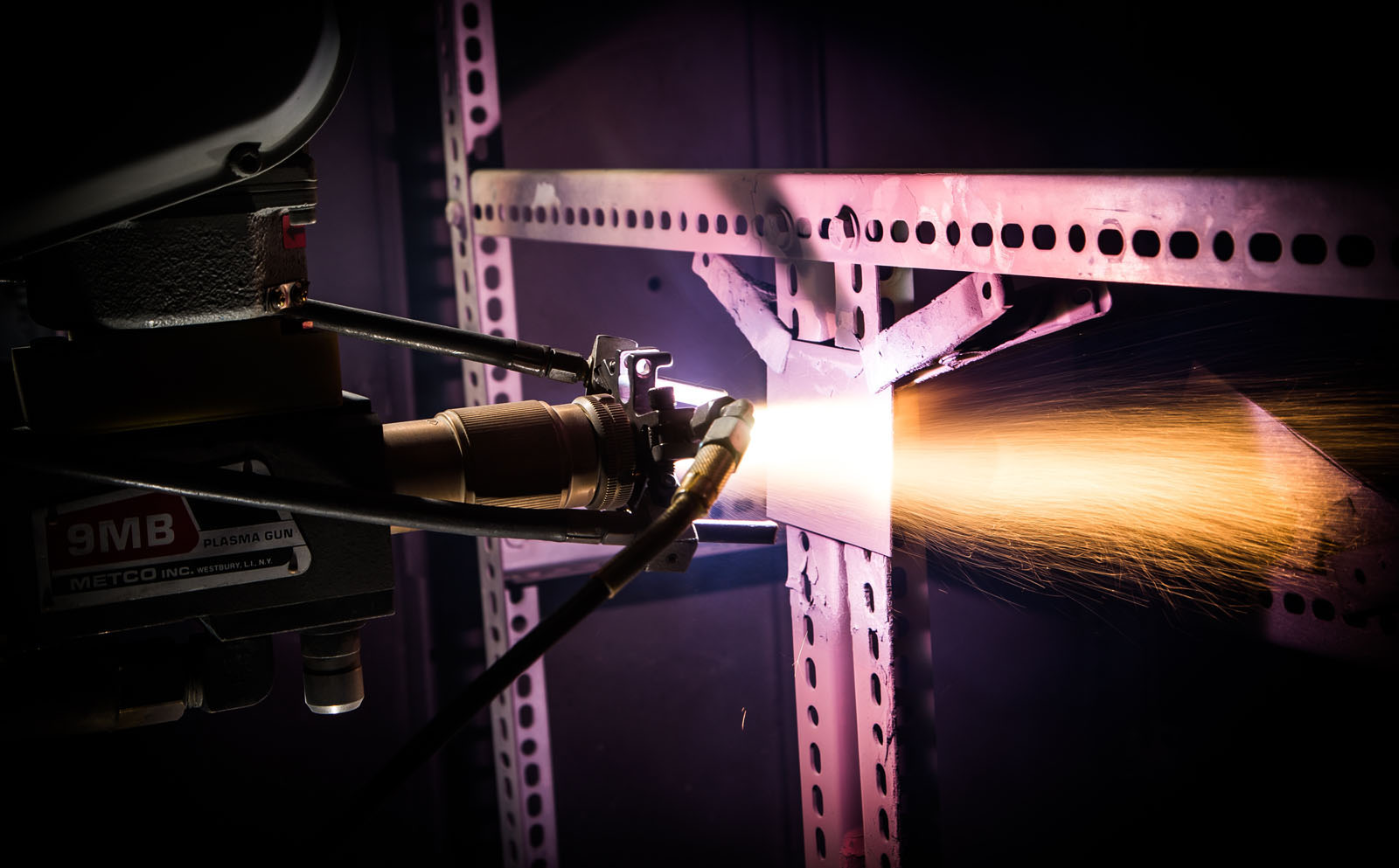

But what material to use wasn’t straightforward, Swartz said. Laser powder bed fusion (the additive manufacturing technique the team would use) relies on metal powders, in this case aluminum, which a laser will melt to form the designed part layer by layer. The powders frequently contain trace metals that, depending on their concentration, can significantly alter the material’s properties, making it stronger or weaker, more brittle or more malleable. What’s more, the power of the laser, how fast it scans, how much overlap there is between adjacent laser paths, and what machine is used also alter the final product’s material properties.

“You’re not just picking an alloy for the application; you’re picking an alloy and processing parameters that then result in your final material,” Post said.

Using CHAPS-D’s required material characteristics as its guide, the team whittled the field of possible materials down to just three alloys. Then, it had to figure out a test-and-evaluation framework to isolate the best alloy and the ideal manufacturing process.

Steve Storck, chief scientist of manufacturing technologies at APL and a paper co-author, had already started paving the way. In a previous internal project, his team had created a process that uses fast modeling, a rapid design procedure with quick sampling techniques. As a result, APL now has some of the fastest methods in the world to develop material properties for additive manufacturing processes, he said, in some cases accomplishing in a week what used to take about three years to complete.

“This new technique allows APL to develop materials faster than the field,” Storck said. “We’ve developed machine learning and down-selection techniques that allow us to efficiently see how each variable couples together and how that ultimately impacts the end performance.”

Leveraging this expedited technique and tailoring it to CHAPS-D’s specific material requirements, the team isolated a material and process in just six months. It settled on a high-strength aluminum alloy called Scalmalloy, the “sweet tea of aluminum,” as Storck put it, because the same process used to supersaturate sweet tea with sugar — heating it up — is used to supersaturate Scalmalloy with the element scandium.

The material still proved tricky to print because the design needed a significant number of supports. It took the team four tries to get the print just right, and because of its optimized design, the final product appears otherworldly — a hunk of slate-gray metal with gapes and crisscrossing struts that make it look almost alive, even alien.

“The first time I saw it, I thought, ‘This looks like something from outer space, not something we put into outer space,’” Zimbeck quipped.

New Applications

Figuring commercial companies and other organizations interested in additive manufacturing might find their process useful, Post received funding to pull together the paper and, through an internal grant, present the project at the 2023 TMS meeting. Ten months later, the team was notified they had won the awards.

“The project really is a great example of how we at APL use additive manufacturing to enhance technologies or enable novel capabilities that otherwise weren’t possible,” said Morgan Trexler, manager of the Science of Extreme and Multifunctional Materials program in APL’s Research and Exploratory Development Mission Area. “This is a nice example of leveraging strong research to enable a new capability for a mission application.”

At APL, the technique has quickly found life in other projects, including space, undersea and hypersonics applications.

As for the CHAPS-D instrument, the team is working on building a flight version in preparation for its scheduled test aboard a King Air B200 airplane this September.