Press Release

Johns Hopkins APL Forges Pathway to Stronger Alloys for Extreme Environments

At around 2,500 degrees Fahrenheit, steel melts. When aluminum is exposed to moisture and oxygen, it corrodes. While these conventional alloys are well suited to everyday environments, they fold under abnormally excessive exposure to extreme heat, cold, pressure and other conditions. And with the nation conducting more and more operations in extreme environments, such as space and the Arctic, the need for alloys that maintain strength under these conditions is critical.

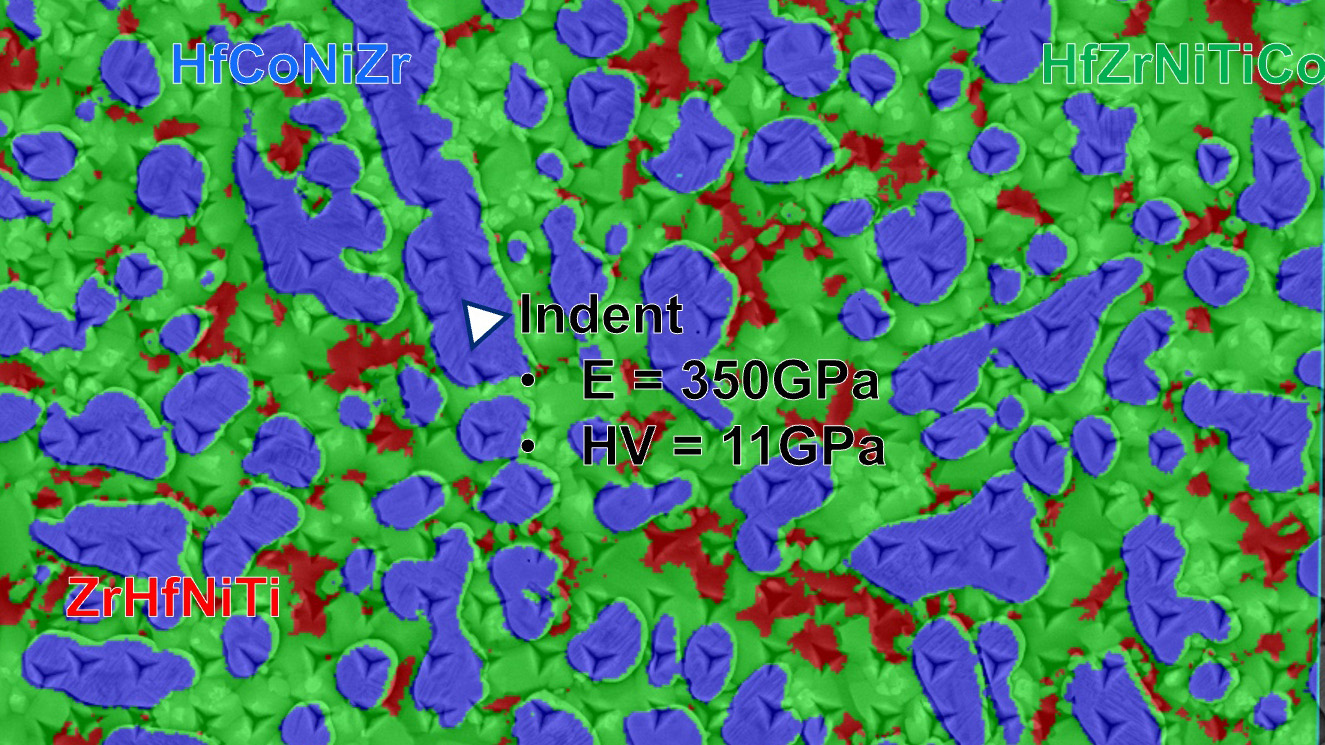

Multi-principal element alloys (MPEAs), which are made up of several elements in roughly equal proportions, can be better suited for extreme environments because their high strength, hardness and toughness over a range of temperatures. In addition, MPEAs often exhibit excellent corrosion resistance and thermal stability, and can display unique functional properties useful for electronic or magnetic devices.

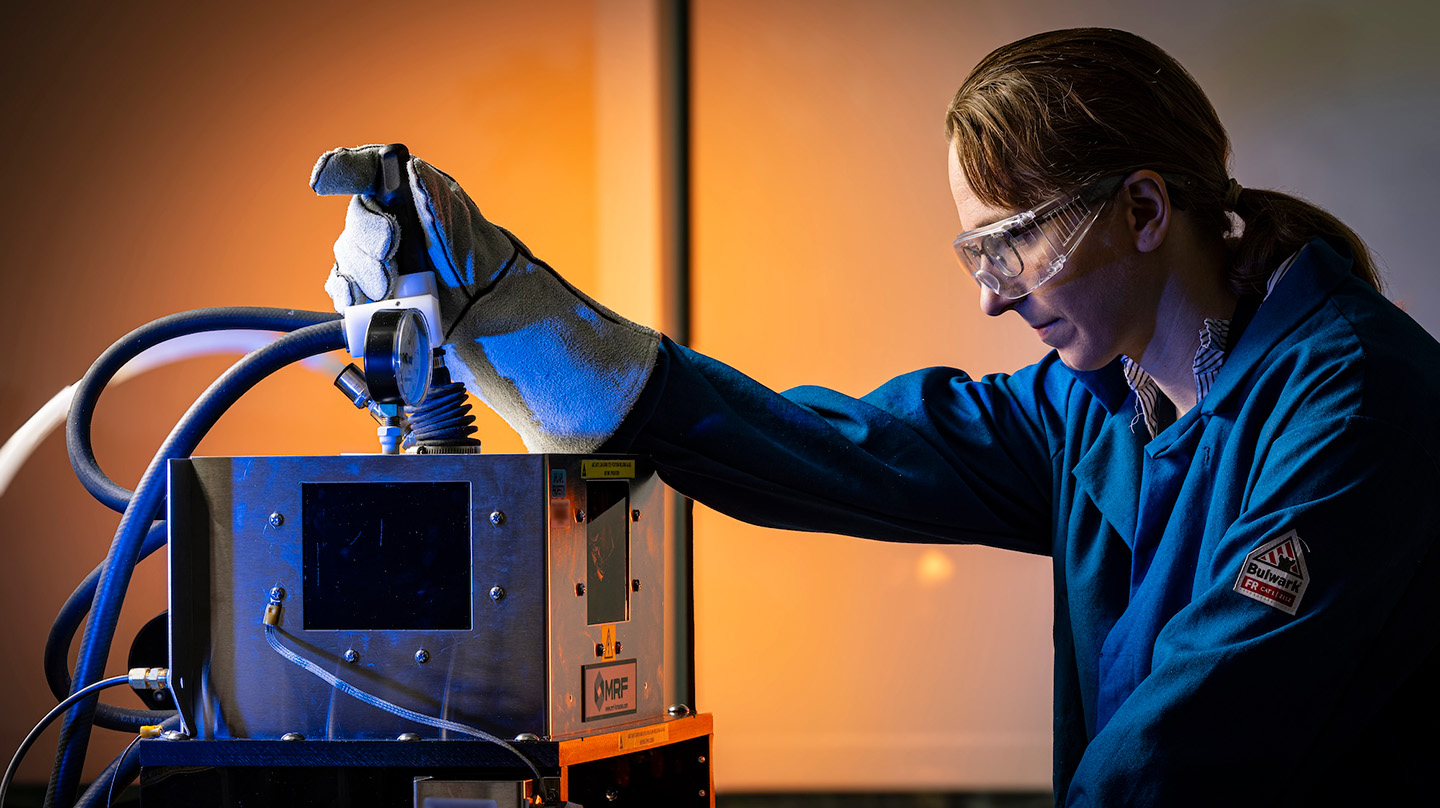

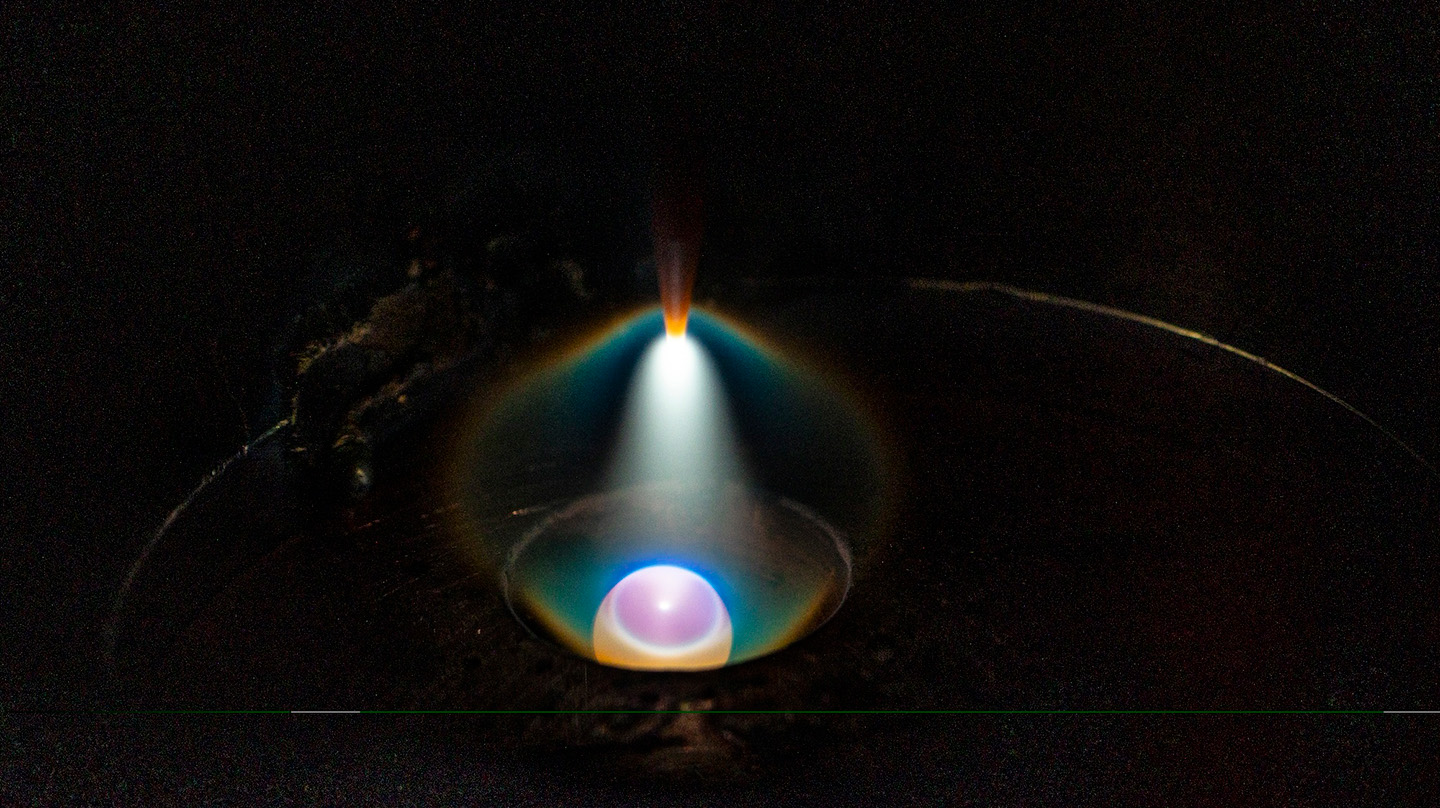

Researchers from the Johns Hopkins Applied Physics Laboratory (APL) in Laurel, Maryland, are accelerating MPEA design by creating complex microstructures that provide composition information from only a few samples. These samples, however, comprise many localized samples that are rich in data. The team’s new pathway automatically links alloy phases — distinct materials formed when an alloy is heated or cooled — to their mechanical properties. Publishing their work in the journal Data in Brief, the researchers described a design capability they used to synthesize 17 unique MPEA compositions.

“Designing MPEAs is challenging because every small change in composition can result in large changes in material formation and properties,” said Morgan Trexler, program manager for Science of Extreme and Multifunctional Materials at APL. “This new capability provides a path for researchers to quickly create and analyze thousands of local data within bulk samples, which will intelligently inform the design of new materials and enable rapid material discovery.”