News

Johns Hopkins APL Develops Methods to Capture and Destroy ‘Forever Chemicals’

Perfluoroalkyl and polyfluoroalkyl substances, or PFAS, are fluorine-containing chemicals found in many household products, such as nonstick cookware, food packaging, cleaning products and stain-resistant carpets; they are also a major component in firefighting foams.

Multiple studies have linked PFAS exposure to harmful health effects in humans and animals, and without a natural way to break them down, the chemicals persist in soil and contaminate the environment — including water. The Environmental Protection Agency recently declared PFAS an urgent public health and environmental issue facing communities across the United States.

Scientists from the Johns Hopkins Applied Physics Laboratory (APL) in Laurel, Maryland, however, are developing several technologies to capture and destroy these so-called “forever chemicals.”

In two recent studies, the APL team demonstrated an enhanced filtration technique to capture PFAS and an ecofriendly way to destroy them. Together with a previously published electrochemical destruction technique, APL is building a portfolio of technologies aiming to enable full PFAS remediation.

The challenge in removing PFAS from the environment is to capture them. Currently, that can be done using activated carbon or ion exchange resins. Both solutions are relatively expensive and difficult to implement in practice; they also tend to miss smaller but equally problematic “short-chain” PFAS.

“There are thousands of PFAS compounds in the world, and the scientific community has discovered that short-chain PFAS are particularly difficult to both capture and destroy,” explained James Johnson, an organic chemist who leads APL’s PFAS capture work.

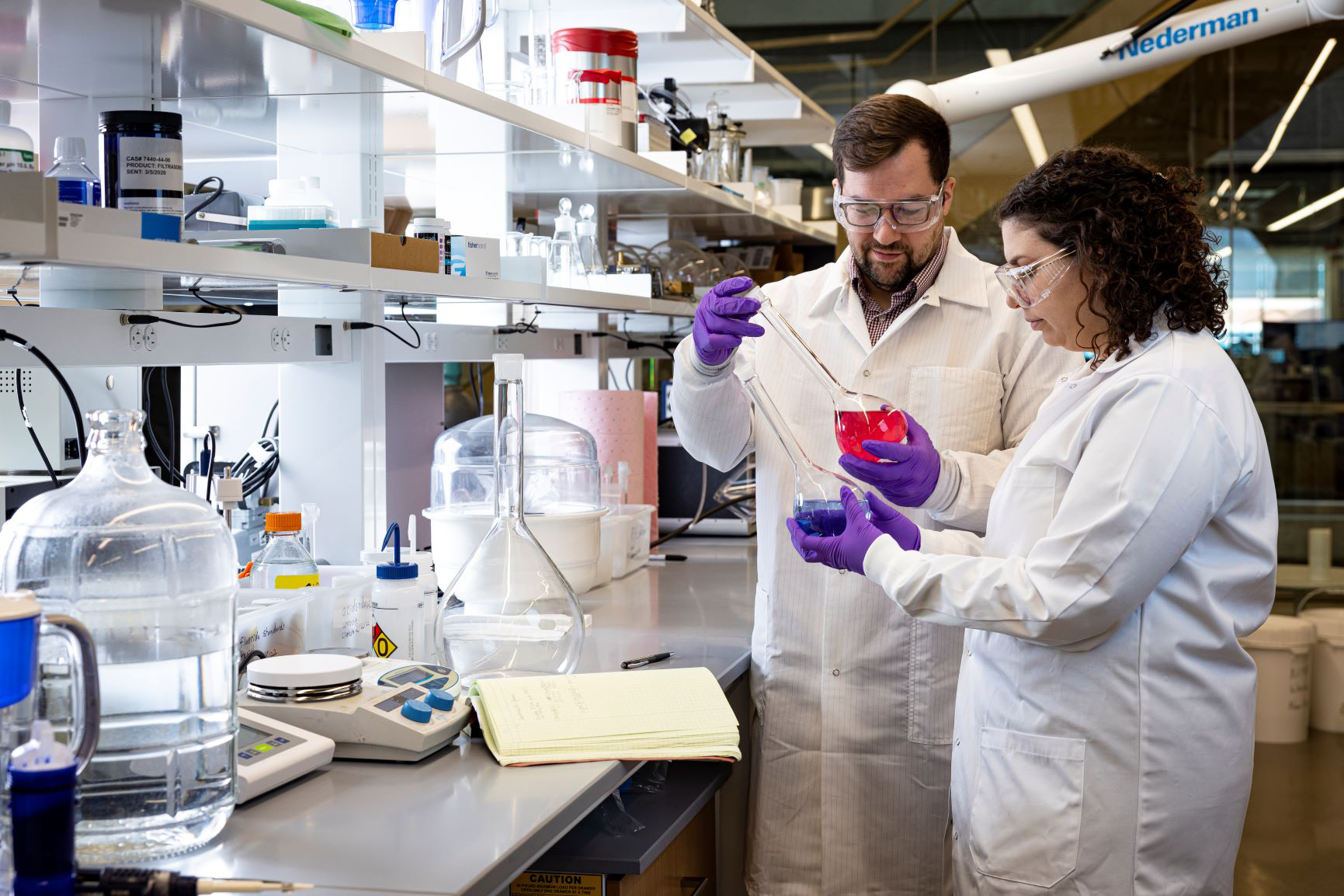

Johnson and a team of APL researchers, which included Michael Salerno, Danielle Nachman, Nam Q. Le, Jesse Ko and Zhiyong Xia, responded to those challenges by developing a cost-effective filtration method that uses novel amphiphilic functionalized membranes — films that are slightly charged on one side and neutral on the other. This selectively traps molecules, so when the researchers pumped PFAS-contaminated water through a roughly quarter-sized sieve that contained the amphiphilic functionalized membranes, the PFAS remained trapped while the water passed through.

“Our filtration technology demonstrated greater than 90% removal of 15 out of 18 PFAS defined in the EPA declaration, with significantly enhanced capture of the short-chain molecules compared with alternative capture technologies,” Johnson said.

The strategy expands on research from several years ago that used the silicon-based molecules called linear fluorinated amphiphilic silanes to remove more than 99% of PFAS. This time, however, the researchers used a nonfluorinated substance to reduce cost and use as little fluorine as possible. APL’s current focus is scaling this technology up for larger applications.

Filtration methods, however, still come with drawbacks. While they effectively remove PFAS from primary waste streams, they generate ancillary waste from the contaminated filter. Captured PFAS molecules that return to the waste stream intact could recontaminate the environment. And the strong carbon-fluorine (C-F) bonds that fortify PFAS’ robust stain and firefighting properties also make the molecules nearly impossible to destroy.

Credit: Johns Hopkins APL

“The most popular PFAS destruction method used commercially today is incineration, which requires extremely high temperatures and high-energy input, is expensive and can release PFAS compounds back into the environment,” explained Leslie Hamilton, a materials science engineer in APL’s Research and Exploratory Development Mission Area. “APL’s destruction methods are designed to operate at or near room temperature, without the use of harsh chemicals or environments.”

In addition to previously published electroactive destruction techniques, the APL team recently developed a strategy that utilizes UV-Fenton chemistry — an advanced oxidation process that leverages hydrogen peroxide and ultraviolet light to create highly reactive oxygen species capable of breaking PFAS molecules’ strong C-F bonds.

“The reaction is catalyzed by a magnetite nanoparticle, which is a naturally occurring, eco-friendly mineral that occurs in soils,” explained Danielle Nachman, a geochemist and leader of APL’s PFAS destruction work. “One of the many benefits of this method is that we're using materials that are environmentally friendly themselves, reducing the amount of downstream water processing.”

In addition to being safe and cost-effective, the method is incredibly efficient. “We’re seeing greater than 90% destruction of 14 out of 18 common PFAS using the UV-Fenton method,” said Nachman, adding that the team plans to continue testing to improve reaction efficiency and target those difficult-to-destroy short-chain PFAS.

Another plus: The developed technologies use readily available, environmentally friendly materials that are easy to scale. The PFAS-capture materials can be applied to any standard filter, and the PFAS-destruction technologies are designed to be implemented in water treatment systems from homes to filtration plants — and may eventually protect communities across the country from these hazardous chemicals.