Press Release

Accelerating Materials Research With AI Keeps Johns Hopkins APL Researchers Ahead of ‘Impossible’ Challenges

From the heat shield coating for NASA’s historic Parker Solar Probe to coatings for hypersonic vehicles and adhesives for underwater applications, researchers at the Johns Hopkins Applied Physics Laboratory (APL) in Laurel, Maryland have shown how materials development is central to innovation — even enabling what was previously impossible.

But researching novel materials — and in particular, characterizing their properties to ensure they’ll function as intended — is time consuming, resource intensive and expensive.

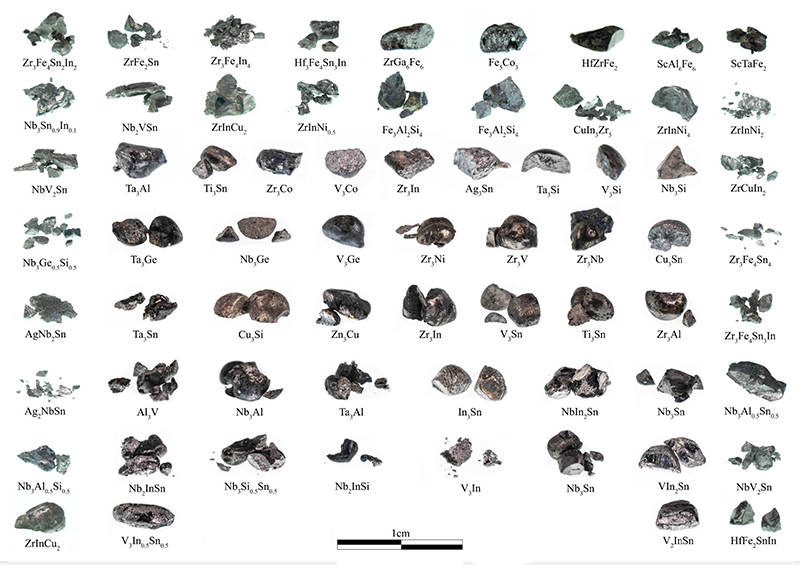

“The standard approach to materials development is, you create a batch of 50 samples or so, examine each one in detail to determine its structure and physical properties, and then conduct tests to gauge their performance,” said Morgan Trexler, who leads the Science of Extreme and Multifunctional Materials program in APL’s Research and Exploratory Development Department (REDD). “And then you tweak one variable and do it again, and again, and again, until you get the right material.”

“Current approaches to novel material design and discovery, whether they are based on theory or experiment, require significant amounts of data,” added Christopher Stiles, a senior computational materials researcher in REDD.

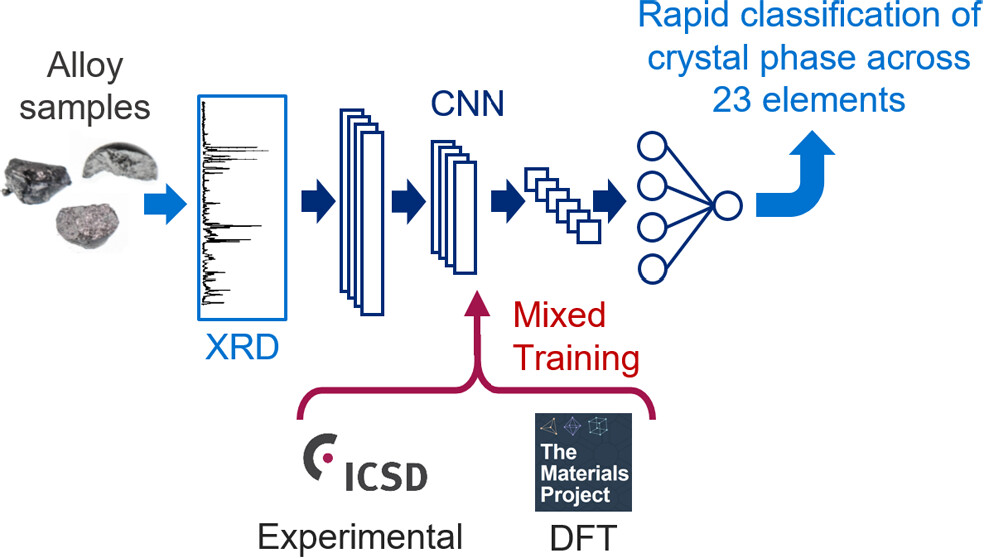

In an age when artificial intelligence (AI) and machine learning (ML) models can process vast quantities of data, and additive manufacturing and synthetic methods can rapidly produce samples of new materials, a new paradigm of materials characterization is required — one that can take advantage of cutting-edge software techniques and hardware platforms. APL is working on multiple applications in this space, leveraging its expertise in AI/ML, modeling and simulation, and materials science, as well as its additive manufacturing capabilities, to accelerate the characterization and analysis pipeline.

“When characterizing materials, there are frequently trade-offs between accuracy, time and throughput,” said Eddie Gienger, a senior materials researcher in REDD. “Traditionally, you’re working with only a few samples that are physically large, and it takes time to arrive at precise values as recommended in historical standards. But when you are trying to invent a new material, you typically make tiny amounts of material, and our thinking is, you can trade precision and accuracy for high throughput and collecting a lot more data that you can use to train AI/ML models.”