News

Researchers Sidestep Cracking in Additive Manufacturing of Refractory Metals

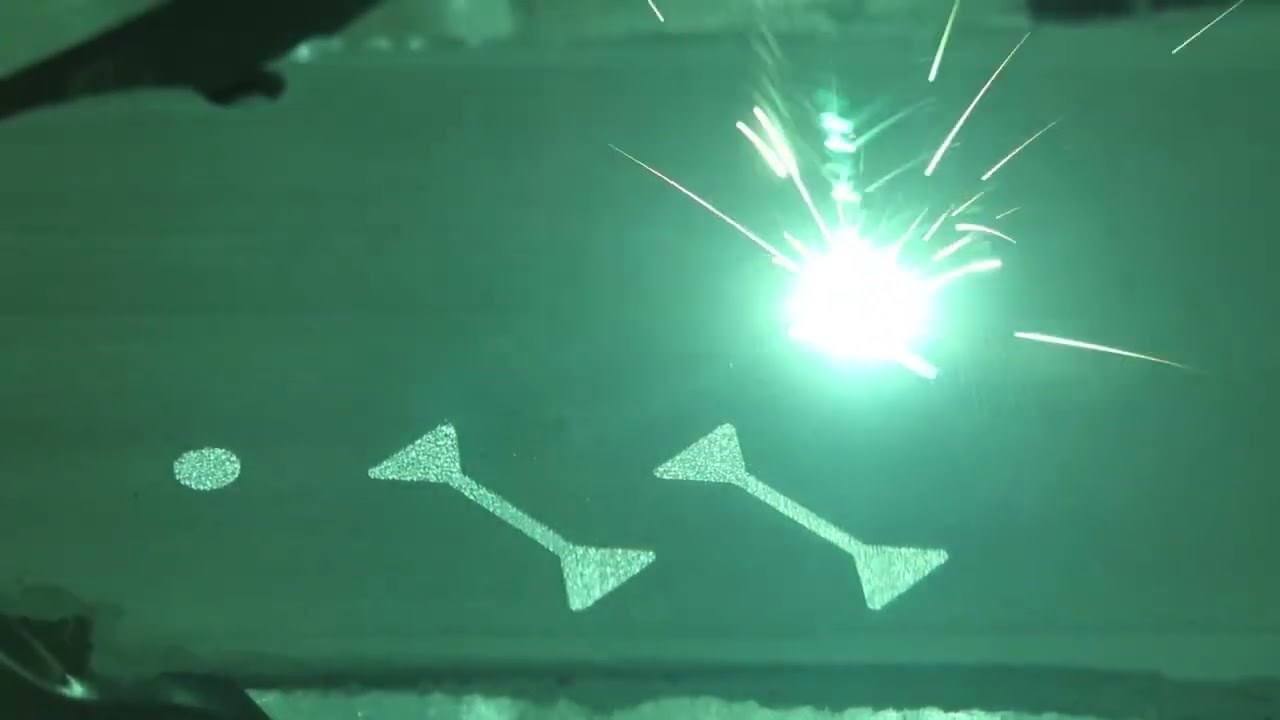

Researchers at the Johns Hopkins Applied Physics Laboratory (APL) in Laurel, Maryland, have made significant strides in 3D printing refractory metals. This small group of elements, including tungsten, tantalum, molybdenum, niobium and rhenium, is highly desirable for applications in extreme environments because of their high density and high melting temperature.

“Refractory materials formed into complex geometries are of interest for use in a variety of high-temperature applications ranging from hypersonics to nuclear reactors,” said Morgan Trexler, who manages APL’s Science of Extreme and Multifunctional Materials program. “Additive manufacturing provides the opportunity to bring new life to these materials, allowing us to form them in ways we couldn’t before.”

In a recent paper about additive manufacturing of tantalum, a team of APL researchers discovered that minimizing porosity (a common objective in additive manufacturing) is not the highest priority when engineering these specific materials.

“Refractory metals are very different from traditional materials,” said Gianna Valentino, the lead author on the study. “Because of their unique properties, they cannot be treated the same as more standard additively manufactured materials.”

The same characteristics that make refractory metals highly desirable also make these materials extremely difficult to work with. Because of their high melting points — exceeding 4,000 degrees Fahrenheit (2,200 degrees Celsius) — they must be heated to extreme temperatures to be additively manufactured. When processed at such high temperatures, refractory metals are susceptible to extensive cracking, which is most detrimental in terms of overall performance.

Working with Valentino and Trexler, additive manufacturing engineer Bobby Mueller, materials scientist Andy Lennon and metallurgical engineer Alex Lark discovered a way to reduce cracking in additively manufactured refractory materials.

That opened up a larger world of possibilities for their application. For example, researchers could print complex lattice designs impossible to achieve through traditional manufacturing, enabling lightweight structures capable of surviving high temperatures.

“There’s a balance to be struck between porosity and brittleness,” Valentino explained. “The ability to minimize crack formations must be prioritized for all refractories.” This optimization results in greater-than-normal porosity in the final material — more than what is considered standard for other 3D-printed metals — but minimizes cracking.

The APL team has optimized refractory alloy compositions and processing conditions for alloys of all refractory group elements. The approaches developed thus far have resulted in high-quality refractory alloys and demonstrations of fabrication into complex geometries.

“Refractory materials are critically important to several national security applications,” Trexler said. “The capability and expertise to manufacture refractory metals in complex geometries could enable new possibilities for the future in energy and defense applications.”