News

Johns Hopkins APL Materials Experts Explore Ways to Fortify Vehicles, Buildings

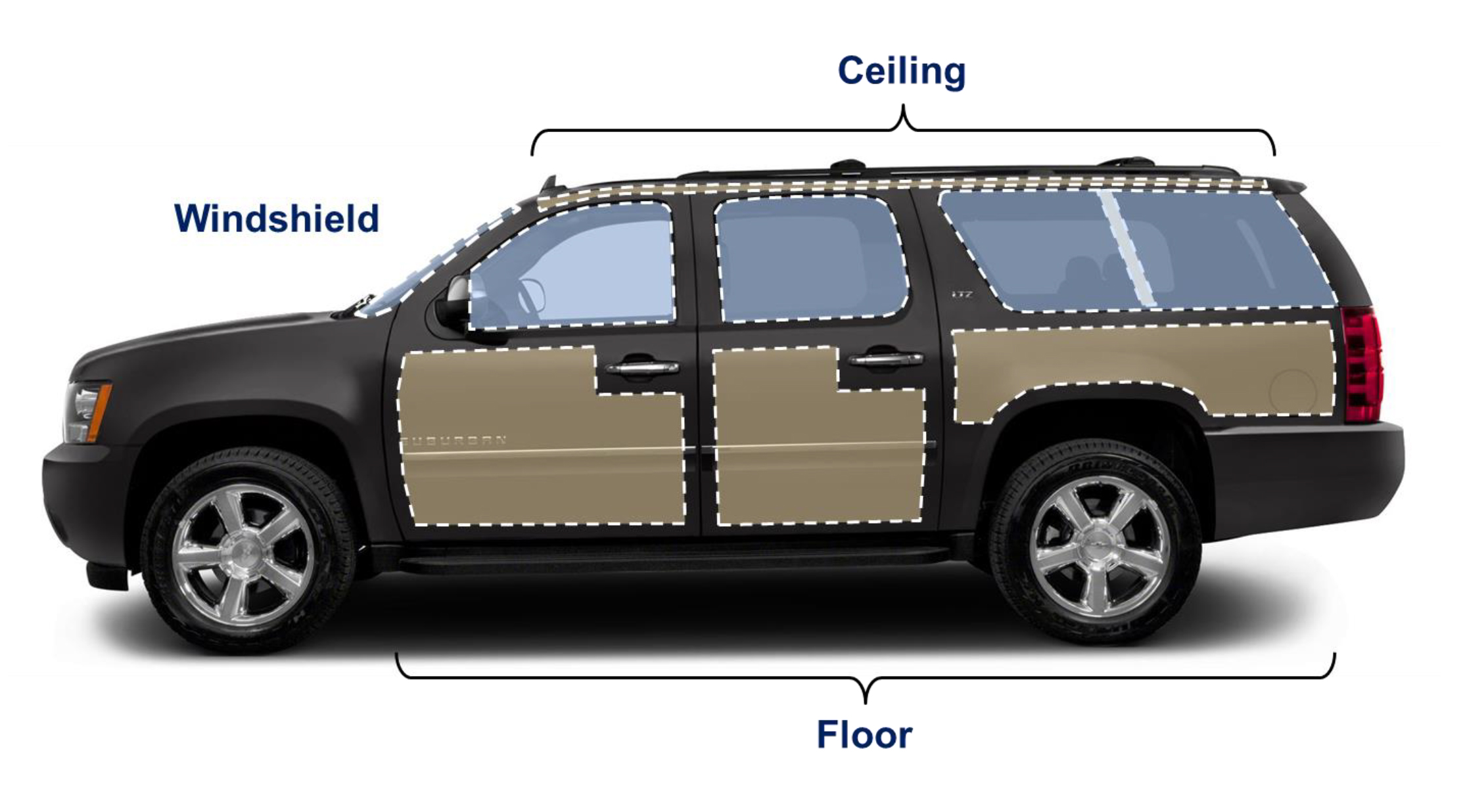

Ambassadors and dignitaries are deployed to some of the most dangerous places in the world. The Department of State’s web of security for these personnel includes a fleet of vehicles fortified with armor plating, bullet-resistant glass and run-flat tires or inserts.

“The black Chevy Suburban is ubiquitous at overseas posts,” noted Adam Maisano, a materials scientist at the Johns Hopkins Applied Physics Laboratory (APL) in Laurel, Maryland. “There are only a handful of vehicles that can bear the weight of the necessary armor. It makes them instantly recognizable.”

Six years ago, the Department of State asked APL to investigate the use of commercially available, lightweight ballistic armor options and integrate the most effective option into a Chevy Suburban.

“The main motivation for employing lighter armor is that it would enable integration into vehicle models beyond the few currently capable of handling the additional weight,” explained Maisano, the project’s manager. “With lighter-weight armor and more vehicle choices, the presence of diplomats would be less obvious.”

This task began a yearslong collaboration with the department to better protect U.S. embassies and consulates. APL has extensive expertise in evaluating armor system performance, with staff members specializing in materials science, ballistics and blast testing, and data analysis and statistics.

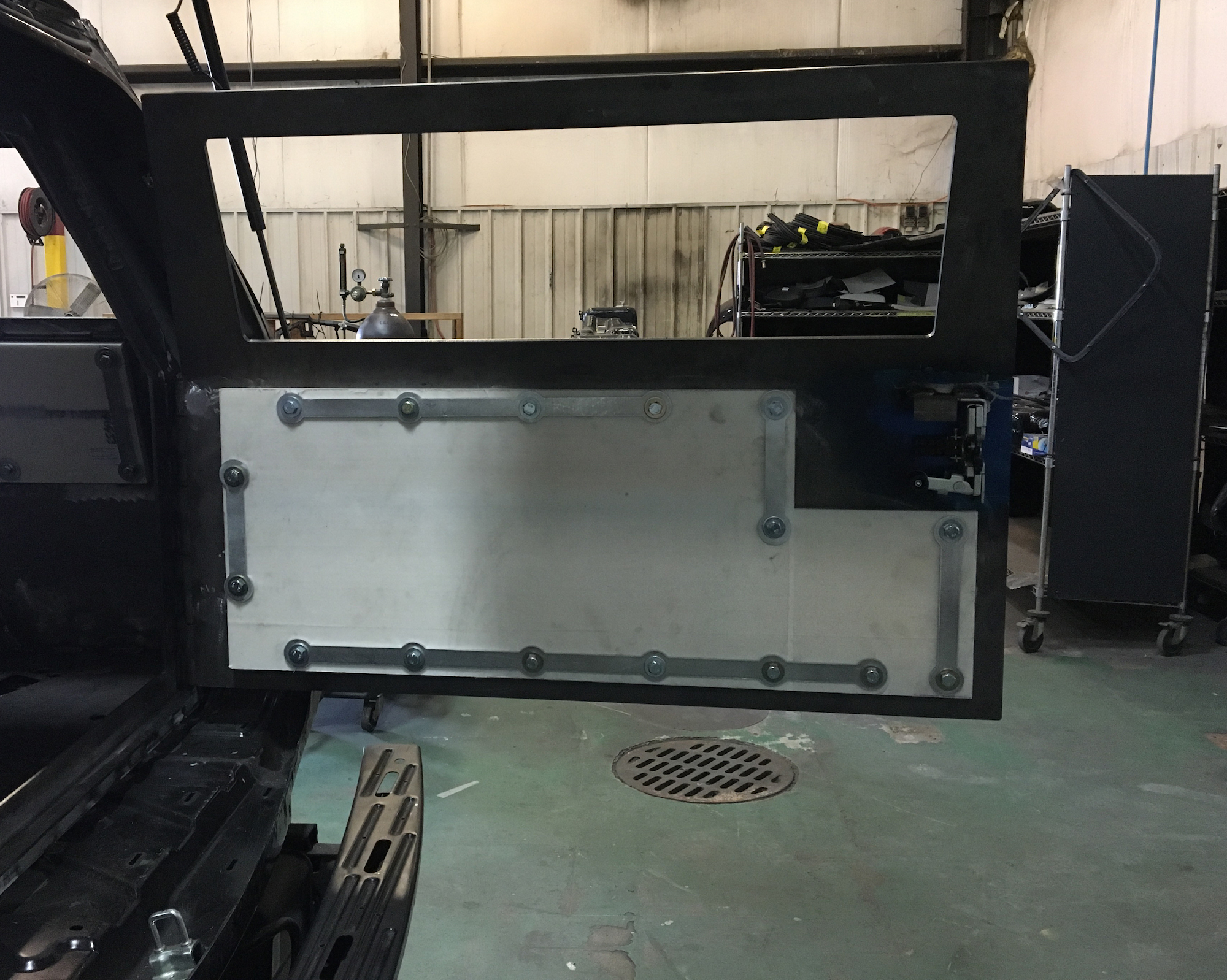

“For that initial task, we scoured the industry to identify opaque and transparent armor materials that met Department of State requirements, measured their capabilities against one another and retrofitted a vehicle to evaluate the materials’ performance,” Maisano said.