Press Release

Creating Food From Thin Air: The Future of Nutrition

For researchers at the Johns Hopkins Applied Physics Laboratory (APL) in Laurel, Maryland, the challenge of feeding people during times of crisis or conflict is an opportunity to dramatically reinvent how food is made: out of almost nothing.

“Yes, we are aiming to create food from thin air,” said Collin Timm, a chemical and biological engineer at APL. “It would be a revolutionary capability to be able to produce food on demand in any setting.”

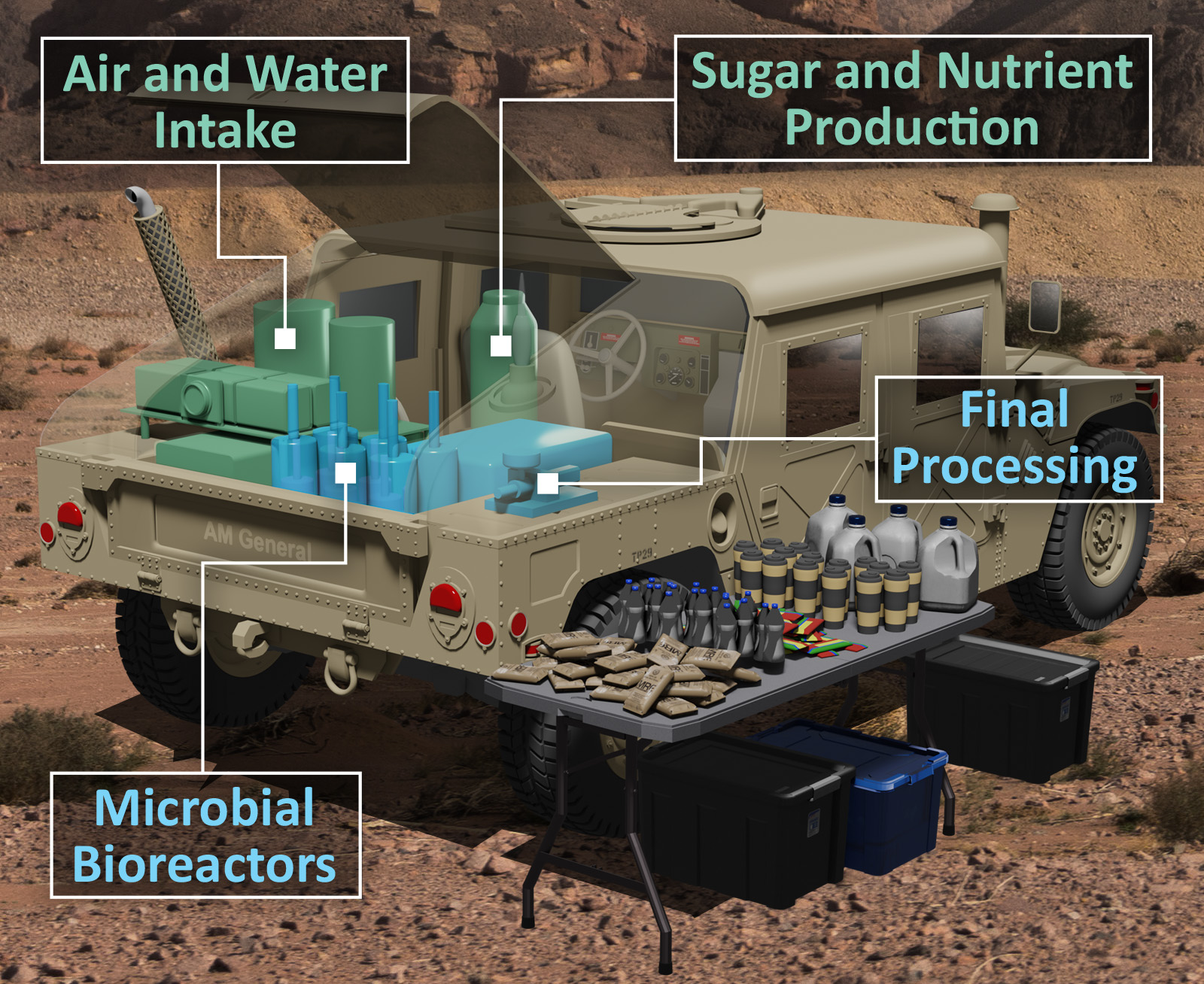

Timm is the principal investigator for one of four teams selected for the Defense Advanced Research Projects Agency’s (DARPA) Cornucopia program. He leads the APL research team in attempting to unlock the potential to produce nutritionally complete, palatable foods in the field. The group is using electricity to capture water, carbon dioxide, nitrogen and trace minerals from the air and then producing a rich, glucose-based material (called feedstock) on which to grow microbial food products.

APL’s approach, dubbed RePLICaTE — for Reducing Provisions and Logistics Inputs through Calorie Transformation from Electricity — is focused on delivering a working prototype, demonstrating a leap forward in food production on demand. Collaborators on the project include the Johns Hopkins University, North Carolina State University and Meridian Biotech.

The Feedstock Is the Key

Feedstock refers to a raw material that is used as fuel or converted to another form of fuel or energy product. For example, crude oil is a feedstock used to create gasoline, corn is used to produce ethanol, and soybean oil is used to produce biodiesel.

“Our process is focused on generating a central, rich feedstock from the components in air to support the growth of food microbes,” explained APL’s William Stone, a molecular biologist overseeing this aspect of the project. The team will capture carbon dioxide from the air and reduce it into simple organic molecules, such as formate and acetate, using sequential chemical reactors. Those products, in turn, will be converted into sugars.

“We are using upstream technologies to convert air and electricity into molecular building blocks, such as sugars and fixed nitrogen, that are required for microbes,” Stone said. “Downstream food-safe microbes then use this feedstock to efficiently produce all the macronutrients and vitamins to be included in food products. Marrying the upstream and downstream processes is a complex systems integration challenge that we are well prepared to tackle.”

To develop these upstream complex processes, APL is collaborating with experts at the Johns Hopkins Ralph O’Connor Sustainable Energy Institute who specialize in creating useful products from atmospheric carbon.

“We aim to extract as many of the nutrients microbes need to produce food from the air as possible.” Stone said. “We will even capture dust and other particulate matter and extract trace minerals like iron and magnesium that are needed for nutritionally complete food products.”

All in Good Taste

The team is also focused on another important part of the eating experience: taste.

“We are attempting to genetically engineer the production of vitamins and flavor components, like butter or vanilla, in organisms generally regarded as safe by the FDA for human consumption,” said Julie Gleason, a molecular biologist at APL.

In addition to the flavor engineering work led by APL, Meridian Biotech is identifying nutritious, palatable microbes and processing them into food formats. Meridan’s texturization process converts bacteria and fungi into ready-to-eat microbial shakes, bars and jerkies. North Carolina State University brings expertise in developing novel technologies for engineering diverse organisms. “The goal is to create a nutritionally complete tasty meal replacement bar or shake,” Gleason added.

One of the trickiest challenges, Timm said, is integrating these chemical and biological operations into a single process. It poses design and control challenges such as balancing carbon and nitrogen capture ratios, optimizing the production of the RePLICaTE feedstock, and allocating energy efficiently to produce and process the final product.

DARPA has also challenged the teams to create a manufacturing and housing system that could fit on the back of a truck, which deployed troops could use to make nourishing and appetizing food on demand in remote locations, removing the need for costly and vulnerable food supply chains.

The current primary source of nutrition in many military operations — called Meal, Ready-to-Eat, or MRE — is not recommended as a sole source of food for long missions, not approved for civilian use and not tailored for age and gender differences.

“Our solution has got to lend itself to military field operations and disaster relief efforts,” Timm said. “So, we are aiming for something that fits the payload of a standard Humvee.”

Leveraging Soldier Support

This new program benefits from APL’s decades of work on projects designed to directly support soldiers in the field. Timm noted that the Laboratory has, for some time, focused on unburdening the warfighter and ensuring access to resources on demand.

Recently, APL scientists have undertaken internally funded projects to produce glucose from microbes and engineer microbes for food production.

The team is also motivated by the impact RePLICaTE could have on the planet’s changing climate. Those early research projects provided critical proofs of concept and preliminary data for RePLICaTE, APL’s latest foray in a growing effort to address climate change and its impacts.

“As part of our work in this area, we’ve been very interested in the resilience of food systems, and we’ve been investing in the development of technologies to provide for basic needs when climate change-induced extreme weather strikes,” said Marisa Hughes, the environmental resilience research lead in APL’s Research and Exploratory Development Department.

“This system has the potential to transition to Department of Defense expeditionary partners and cross-agency responders to disasters and displacements,” she said. “With further refinement, larger food-on-demand systems could expand to alleviate food logistics limitations across the armed services and enhance homeland security by increasing resilience of domestic food supply chains. Furthermore, if paired with renewable energy, this could produce food products with a drastically reduced carbon footprint.”

Making climate-informed decisions, adapting our forces to a climate-changed world, and contributing to our nation’s climate goals are among the many challenges that require bold innovations. APL’s Research Frontiers Forum on June 8 will explore goals, gaps and game-changing research in climate change and national security.

Learn more about these efforts at jhuapl.edu/ourwork/climate.

This material is based on work supported by the Defense Advanced Research Projects Agency (DARPA) and Naval Information Warfare Center Pacific (NIWC Pacific) under Contract No. N66001-23-C-4007. Any opinions, findings and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect the views of DARPA or NIWC Pacific.