News

Subtracting Time From Additive Materials Development

There are thousands of existing metals and alloys, but achieving high-quality additively manufactured materials can be challenging. That means the use of promising additively manufactured metals and alloys that could perform well in extreme environments is limited. To fix that, researchers at the Johns Hopkins Applied Physics Laboratory (APL) in Laurel, Maryland, developed a rapid additive manufacturing materials development framework — expanding the reach of additive manufacturing to new materials.

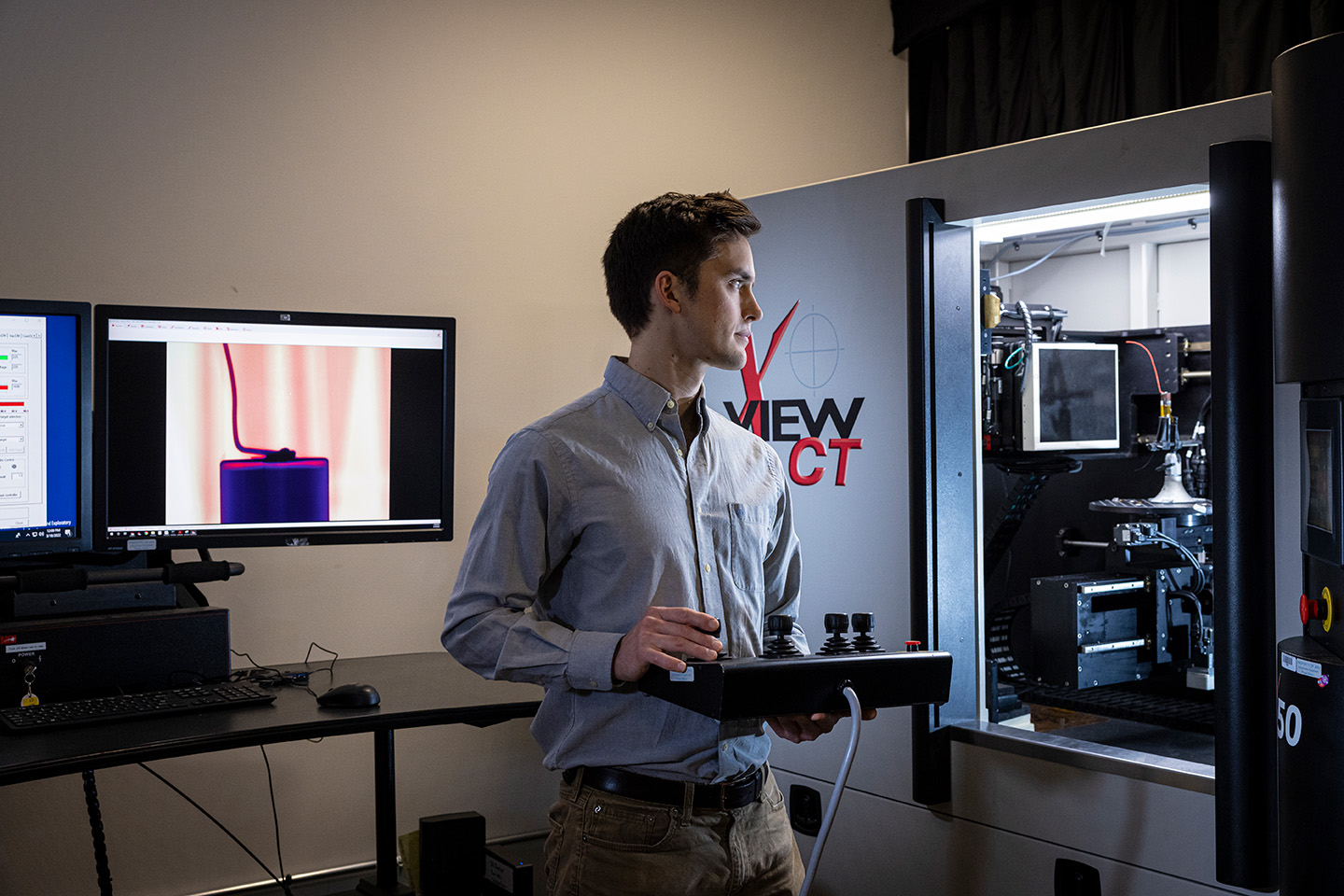

It takes months, sometimes years, to generate optimal processing conditions for a new material. The APL-developed materials development framework condensed that timeline using simulation and novel measurement techniques. The framework consists of four steps, achievable in a matter of days: computational fluid dynamics (CFD) modeling, a design of experiments and fabrication, X-ray computed tomography (XRCT) and high-throughput testing.

“This capability changes what we can use additive manufacturing to do,” said Steven Storck, a senior researcher specializing in manufacturing science. “When I started at APL years ago, there were just a dozen or so metals available for additive manufacturing. There is still an abundance of metals available where parameter sets don’t exist. And often, even when there is a standard parameter set from the manufacturer, it doesn’t meet the specific application needs. I’m working on numerous projects now that rely on this method, and without it those projects would simply not be possible in the required time frame.”

“The standard approach to additive manufacturing is to fabricate redundant parts over and over, which is costly in time and resources,” explained Morgan Trexler, who manages the Science of Extreme and Multifunctional Materials program at APL. “Given the complex, specific applications APL works on, we needed a better way to quickly generate data to help us understand materials formation, resulting material quality, and the impact of the processing and resulting materials structure on performance. We can then tailor laser conditions to get the best possible material microstructure for a particular extreme environment application.”

Rapid Materials Development in Action

From enabling complex metallic shapes that survive extreme temperatures to creating 4D shape-morphing components or producing materials that are nearly impossible to achieve with other types of manufacturing, the framework developed in APL’s Research and Exploratory Development Department is being used extensively across the Laboratory for new material formulations.

One of the projects that relied on this framework improved corrosion resistance in steel additively manufactured parts. APL researchers used the rapid development framework to identify processing parameters for generating corrosion-resistant steel, providing potential for enhancing corrosion resistance and thereby extending use of additively manufactured steel parts in marine environments.

APL researchers have also used this capability to better understand materials that have long confounded additive manufacturing researchers, such as nickel titanium. When APL began research to design 4D shape-morphing components, there were just a handful of studies on printing nickel titanium. The team relied on rapid materials development to unlock the optimal material performance.

Additionally, the APL-led process will help NASA’s Space Technology Research Institute develop state-of-the-art computational models and simulation tools for qualification and certification of additively manufactured parts so that they can be designed, fabricated and used on spacecraft. This envisioned modeling toolset will be validated against experimental data, a process that will be accelerated using APL’s additive manufacturing materials development framework.